### Parametric 2D Design Tools

- Parameterize drawings to avoid tedious future edits

- [Fusion sketch](./sketch.html)

- [Rhino + Grasshopper](https://www.youtube.com/watch?v=mZ_1jC2FrnY&t=2s)

- <a href=http://www.inkscape.org>Inkscape</a> <a href=https://inkscape.org/gallery/=extension/>extensions</a>

- <a href=https://www.blender.org>Blender</a>

- <a href="./blender.html">Blender CAD Sketcher</a>

- <a href=https://www.freecadweb.org>FreeCAD</a>

### Making 3D from 2D

- <a href='http://fab.cba.mit.edu/classes/863.12/people/salzberg/week2.html'>Press-fit constuction

- <a href='https://www.youtube.com/watch?v=GsIi17Xialg'> Slicing 3D objects </a>

- <a href='http://academy.cba.mit.edu/classes/computer_cutting/flexures.png'> Flexures</a>

### Laser cutter

Laser cutting works by focusing the output of a high-power laser through optics at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas.

[Laser types](https://en.wikipedia.org/wiki/Laser_cutting)

* Nd:YAG - The neodymium-doped yttrium aluminum garnet (Nd:YAG) laser uses a solid crystal substance to focus light onto its target.

* 1.06 micron wavelength - [optical reflectivity](Metal_reflectivity.png)

* Does not work well on organic materials (wood, rubber, etc.), ideal for some metals and plastics

* CO2 - uses a gas medium instead of a crystal for focusing light

* 10 micron wavelength

* Works well on wood, acrylic, plastic, and many other materials (especially > 100 Watt)

* Fiber - solid state laser, increasingly popular especially for cutting metal

* Solid gain medium, as opposed to a gas or liquid

* Laser beam amplified with glass fiber

* Spot size up to 100 times smaller compared to CO2

* No optics to adjust or align and no lamps to replace

* Lower operational costs than CO2

* [Jake's laser: Fablight - 1.5kW fiber laser](http://3dfablight.com/)

* [UV laser ablation](https://a-laser.com/uv-laser/) explodes material rather than melting it, which results in a sharper, cleaner edge and less thermal influence

Materials:

* Reflective metals like aluminum and stainless steel are best cut with fiber laser (smaller spot size).

* Nervous System's [quest for perfect plywood for laser cutting](https://n-e-r-v-o-u-s.com/blog/?p=6042) (TL;DR -- contact small-scale manufacturer and specify your own grades, veneers, plys and glue)

* [The secret to clean laser cutting: Designing a better laser nozzle using 3D-printing](https://n-e-r-v-o-u-s.com/blog/?p=8722)

Lasers are also used for additive manufacturing processes like [selective laser sintering](https://en.wikipedia.org/wiki/Selective_laser_sintering).

### Drag Knife Cutting

_From [AXYZ](https://www.axyz.com/us/2019/02/26/drag-knives-for-cnc-routers-expand-creativity/), various CNC attachments for drag knife cutting._

* Various attachments exist for CNC machines to allow for drag knife cutting

* Other machines are built for this purpose (Zund, vinyl cutter)

* Some require special blades, others use common utility knife blades

* Spring force helps keep pressure constant

* Rotary blade (wheel) vs. fixed blade

* Drag knife cutting has been popularized via cheap "craft cutters" like [Silhouette](https://www.silhouetteamerica.com/) and [Cricut](https://hackaday.com/2021/03/15/cricut-decides-to-charge-rent-for-people-to-use-the-cutting-machines-they-already-own/). These suffer from restrictive firmware and obnoxious subscription fees.

* Many DIY solutions to build drag knife cutters from [printers](https://www.youtube.com/watch?v=jZMQ3P8K2wE), [3D printers](https://www.thingiverse.com/thing:4441625), or [CNC routers](https://www.cnccookbook.com/build-drag-knife-cnc-router-mill/).

#### Vinyl Cutting

A vinyl cutter is a type of computer-controlled machine that controls the movement of a sharp blade over the surface of the material. Applications:

* Stickers and signage

* Heat transfer / apparel

* Circuits

_Examples of vinyl cut circuits and "speaker portrait" by [Victoria Shen](https://www.instagram.com/evicshen/?hl=en)_

### Zund Cutter

Zund makes large-scale high-precision CNC systems that use a range of cutting tools. Most commonly, materials are cut with a knife blade that is actively rotated to follow the direction of the cut (therefore not a drag knife). This machine can be used to cut materials that are too toxic or flammable to cut with a laser.

The GSD Fabrication Lab has [great documentation](https://wiki.dev.tlt.harvard.edu/confluence/display/fabricationlab/Zund+Cutter+Tutorial) for using their Zund cutter.

<img src="https://wiki.dev.tlt.harvard.edu/confluence/download/attachments/219567362/Capture.JPG?version=2&modificationDate=1512061260000&api=v2" alt="zund attachments" width="600"/>

_Tool options for the Zund cutter (Credit: Rachel Vroman)_

* Universal Drawing Tool (UDT) - For drawing lines with a pen

* Universal Cutting Tool (UCT) - For most cutting operations

* Electric Oscillating Tool (EOT) - For soft materials such as cardboard, foamcore, or rubber

* Pneumatic Oscillating Tool (POT) - like EOT but with greater blade throw and faster oscillation for thicker materials.

* Driven Rotary Tool (DRT) - For fabrics and fabric-like materials.

* V-Cut Tool (VCT) - For cutting bevels and v-cuts in foam core less than 1/2". (Not Pictured Above)

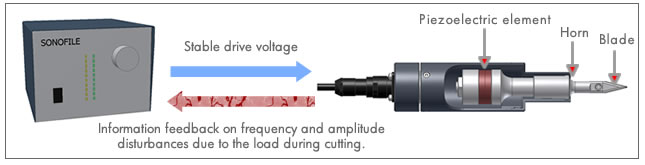

### Ultrasonic Cutting

Piezoelectric transducers create high frequency (20-40 kHz), low amplitude (10-70 µm) vibrations that provide the energy to slice through an object with very little pressure.

[Sonotec Cutter](http://www.sonotec.com/en/tec.html)

[WonderCutter (~$400)](https://www.micromark.com/Wondercutter)

<iframe width="900" height="600" src="https://www.youtube.com/embed/BRzRnUbWMKM" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

### Die Cutting

<a href='https://en.wikipedia.org/wiki/Die_cutting_(web)'>Die cutting</a> is the general process of using a die to shear webs of low-strength materials.

[Die Cut Pattern Generator](https://www.diecuttemplates.com/)

* E.g. rubber, fibre, foil, cloth, paper, corrugated fibreboard, chipboard, paperboard, plastics, pressure-sensitive adhesive tapes, foam, and sheet metal.

* Started as a process of cutting leather for the shoe industry in the mid-19th century.

* Kiss cutting: cut through just one layer of a laminate, used on labels, stamps, and other stickers.

* Rotary die cutting is often done inline with printing.

* Flatbed die cutting is slower than rotary die cutting, but the tools are cheaper. (Better for smaller production runs).

<iframe width="900" height="600" src="https://www.youtube.com/embed/pNtWiF0bPrg" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

### Plasma cutting

* [Examples](https://www.youtube.com/watch?v=Ry4kohKGAfI)

* An electrical channel of superheated, electrically ionized gas (i.e. plasma) is created from the plasma cutter itself, through the work piece to be cut, completing a circuit via a grounding clamp.

* A compressed gas (oxygen, air, inert and others depending on material being cut) is blown through a focused nozzle at high speed toward the work piece.

* An electrical arc is formed within the gas, between an electrode in the gas nozzle and the work piece itself.

* The electrical arc ionizes some of the gas, thereby creating an electrically conductive channel of plasma.

* As electricity from the cutter torch travels down this plasma it delivers sufficient heat to melt through the work piece.

* At the same time, much of the high velocity plasma and compressed gas blow the hot molten metal away, thereby cutting through the work piece.

* Traditionally, plasma cutting was viewed as a messy and rough cut process, but improvements in control technology have tightened tolerances and made the process more precise and accessible. 0.012" accuracy is quoted from [Plasma cutting: Then and Now](https://www.thefabricator.com/article/plasmacutting/plasma-cutting-then-and-now)

* [Plasma cutting basics](http://www.lincolnelectric.com/en-gb/support/welding-how-to/Pages/plasma-cutting-basics-detail.aspx)

* Any conductive material can be cut with plasma. Steel, Aluminium, Copper, Brass, Titanium, etc.

* Precision plasma cutting is [commercially availiable](http://www.plasma-automation.com/Machinery/Plasma-Cutting/Elite-Precision-Plasma-Cutter.php) at [different scales](http://www.modernmachinerycompany.com/plasma-cutting-machines/cnc-precision-plasma-cutting-machines/)

### Oxy-acetelene

<img src='https://upload.wikimedia.org/wikipedia/commons/thumb/1/1f/Brennschneiden.svg/800px-Brennschneiden.svg.png' alt='oxy' width='400'>

_Operating principle of burn cutting (Image: [Wikipedia](https://en.wikipedia.org/wiki/File:Brennschneiden.svg))_

* Uses fuel gases (or liquid fuels such as gasoline) and oxygen to weld or cut metals

* Very affordable, also very dangerous

* Can use the same cylinders with different tips to cut, heat treat, or weld

* Not good for aluminum and other very highly conductive materials because it will just melt everything: <br>

* For mass production oxy-fuel is easy to parallelize: <br>

### Waterjet cutting

Waterjets cut with an extremely high-pressure jet of water, or a mixture of water and an abrasive substance (called garnet). Waterjet cutting is preferred especially for materials that are sensitive to high temperatures.

<img src ='https://upload.wikimedia.org/wikipedia/commons/thumb/5/5d/Water_jet_cutter_head.svg/800px-Water_jet_cutter_head.svg.png' alt = 'waterjet diagram' width = '200'>

_A diagram of a water jet cutter. #1: high-pressure water inlet. #2: jewel (ruby or diamond). #3: abrasive (garnet). #4: mixing tube. #5: guard. #6: cutting water jet. #7: cut material. Image from [Zureks](https://en.wikipedia.org/wiki/Water_jet_cutter#/media/File:Water_jet_cutter_head.svg)_

[Desktop - Wazer](https://www.wazer.com/)

[Omax - ProtoMax](https://protomax.com/?utm_source=omax-quality-ed-light-commercial-application&keyword_session_id=vt~adwords|kt~personal%20waterjet|mt~p|ta~245694010010&_vsrefdom=wordstream&gclid=EAIaIQobChMIsrLh59HB2gIVWksNCh1ylwiyEAAYASAAEgL18PD_BwE)

[5-axis waterjet](https://wardjet.com/products/waterjet/accessories/5-axis?gclid=EAIaIQobChMIjqX91dDB2gIVBEwNCh38BAXDEAAYASAAEgKOUfD_BwE)

[Zahner Metals](https://www.azahner.com/services/fabrication/): large-scale waterjet cutting (and other big machines)

#### Micro-waterjet cutting

[OMAX micro machining](https://www.omax.com/omax-waterjet/micromax)

* can cut lots of materials

* new and improved taper free cutting

* new and improved precision +/- 0.0001"

[OMAX micromax](https://www.omax.com/omax-waterjet/micromax)

<blockquote>"capable of a positioning accuracy of less than five microns while retaining all the advantages of abrasive waterjet machining"</blockquote>

<iframe width="900" height="600" src="https://www.youtube.com/embed/Lg__B6Ca3jc" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>